For programming within the Cutter Location language "CL"

(ProcessAutomation Language) the PC language "CL" has been

implemented. CL language is mainly based on EDS I-DEAS up to version 9 generated

output. Operational dialog has been realized via pull-down-menus

built-up clear functional structures. Information stated in the status

line effectively supports evaluation and familiarization with the

program system. Operational and timing errors are shown in error

windows as either text or information. At the same time problem

solutions and remedies are suggested.

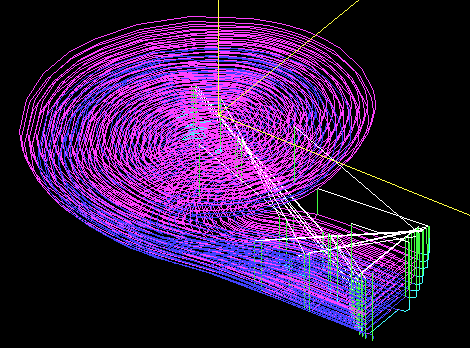

Cutter Location and GISEL have been implemented as components in the isel-control-software for cartesian systems (such as mechanical stage, stroke bracket, XYZ-portal installations with optional round axle A).

Technological programming (interpolation, stating of coordinates, parameters and speed sellings) in the isel GISEL-system has been effected in accordance with the syntax definition of DIN 6602. Corresponding Mnemonics within the CL language criteria have been set for all relevant G- and M-commands.

PARTNO/'Setup-1' UNITS/MM MODE/MILL PPRINT/'OPERATION CATEGORY & TYPE: Milling Volume Clear' PPRINT/'OPERATION NUMBER & NAME: Operation-6-pocket-clear' LOADTL/0, IN, 4, LENGTH, 0.000000, OSETNO, 0 CUTTER/6.000000, 3.000000, 0.000000, 3.000000, 0.000000, 0.000000, 10.000000 PPRINT/'TOOL IDENTIFIER: krogelni 6 mm' PPRINT/'POST TOOL ID: 0' PPRINT/'TOOL STATION NUMBER: 4' MULTAX/OFF ORIGIN/ 0.000000, 0.000000, 0.000000 LINTOL/0.050000 SPINDL/18000.000, RPM, CLW COOLNT/OFF PPRINT/'Start Region 1 -- Depth: -13.683507' RAPID GOTO/51.184319, 82.528565, 16.000028 RAPID GOTO/51.184319, 82.528565, -6.999971 FEDRAT/2600.000000, MMPM GOTO/51.184319, 82.528565, -13.683507 MOVARC/72.490974, 72.508679, -13.683507, 0.000000, 0.000000, -1.000000,$ 23.545098, ANGLE, 25.970990Click here for a full file Cutter Location Sample

Absolute motion @(GN)M(gx),(sx),(gy),(sy),(gz),(sz),(gz2),(gz2) Relative motion @(GN)A(gx),(sx),(gy),(sy),(gz),(sz),(gz2),(gz2) Circular interpolation @(GN)Y(b),(v),(e),(x),(y),(rx),(ry) Park motors @(GN)R(osi) Circle direction @(GN)f(D) Homing speed @(GN)d(sx),(sy),(sz) ON/OFF 3D interpolation @(GN)z(I) Set absolute zero @(GN)n(axs) Select interpolation axses @(GN)e(S) Give axes @(GN)(axs)The following responses from controller are recognized:

2 Stob button presses or motion ended at limit switch 3 Invalid number of axes 4 No axes given 5 Syntax error 6 Out of memory 7 Invalid command parameters 8 Invalid program branching c Invalid loop D Invalid speed G No code in memory for execution z Internal error (CR) Invalid end of command

Contact information:

Leon.Kos [at] uni-lj.siAlternatively soruce code is provided for reviewing and possibly building with Borland BCC compiler 4.55 and Turbo Vision windowing system.